Quality

Just about every precision machining business will talk about quality. But at Precision Components Ltd, we don’t just talk about it – quality goes right through our business, from the way we answer the phone to the delivery of your order.

Dedicated QA department

Quality assurance is a separate business function in Precision Components. Our QA department uses enterprise resource planning (ERP) software from global leader SAP. This forms the basis not just of QA but also the smooth running of the business.

We use our ERP system to provide customers with full statistical reports on quality before anything is shipped. This includes traceability info and all the numbers necessary to verify dimensional results. For some of our clients we even link our systems so they can view real-time statistical information.

People know what to do

Just as we love accuracy in our engineering work, we love it in the office too. It matters to our customers that the paperwork is all in order, that deliveries happen without fail, and that they get to speak with people who understand their business.

When we started to grow Precision Components in the 1990s, we wanted to make sure our people had clear roles and responsibilities. We train and manage our team properly. For all our clients, this means that people know what they are doing. You don’t get a machinist running to get the phone to take a sales call, and you don’t get a QA manager doing the invoicing.

What you do get is a properly managed project. From the time that you send us your drawings, to the machining and coating, the finishing and shipping, everything is under control.

We’re extremely thorough so that clients get exactly what they need, when they need it. So if you have guidelines and rules to work to, we’ll make sure the right people know what to do.

Top-line machinery designed for precision

All our CNC machines come from two leading companies – Mazak and Hyundai. We chose to invest in the best because quality and accuracy are so essential to our clients. We currently have 14 Mazaks, 8 Hyundais and run three sets of Mastercam. And we’re planning to invest in new machinery shortly so that we keep our place as leading, high-tech engineers.

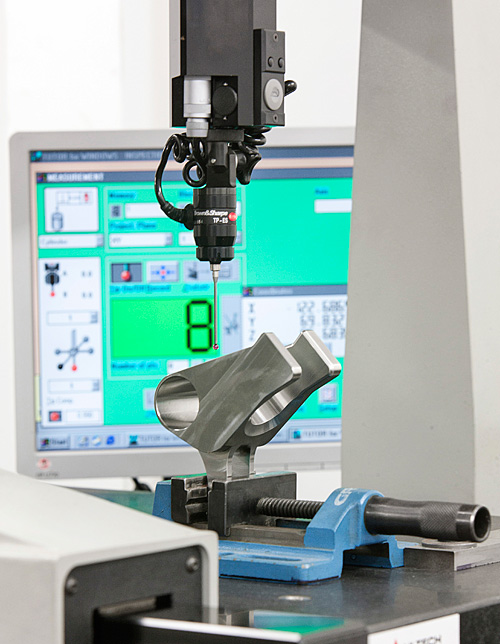

But probably our most important machine is a Brown & Sharpe CNC CMM machine. This measuring machine is essential to quality. It means we can certify machining tolerances on every component that we create. And that means customers get fully audited accuracy.

International standards

All our machines are calibrated to international standards. But it isn’t just international measurement standards that we work to.

Our quality management meets the standards set out in ISO 9001:2015. And we are very passionate about our environmental impact too. When we moved to our new 32,000sq ft premises in 2011, we made a few changes to help us work towards our goal of zero waste output. As well as improved recycling and reducing energy use, we’re also now collecting and re-using rainwater. We’re doing all this whilst working towards ISO 14001, the international environmental management standard.

If you are looking for high-tech, high tolerance engineering from a well-respected business operating on a global scale, please get in touch with Duncan George at Precision Components Ltd.

Phone: +64 9 415 4590

email: duncan.g@pcltd.co.nz